Tel: 01282 787007

Lifting and Slinging Procedures

9 Steps For Safe Lifting and Slinging.

1, PRE USE CHECK.

Before any lifting and slinging takes place a pre shift check must be carried out on the equipment used. This includes checking for, rips, tears, cracks, stitching coming loose, wear, clasps, discoloration, tags, to name just a few. Report any faults immediately.

This is a common step that is missed due to lack of Lifting and Slinging training.

2, SELECT THE CORRECT LIFTING EQUIPMEMT.

Before lifting a load make sure the weight, size, material, shape etc of the load is taken into account before selecting the correct lifting equipment.

3, MAKE SURE THE LOAD IS SECURE.

The correct method of securing the load when Lifting and Slinging is essential. ALWAYS double check the load is secure and will not come loose in transport. REMEMBER a choke hitch reduces what the sling can lift by 20%.

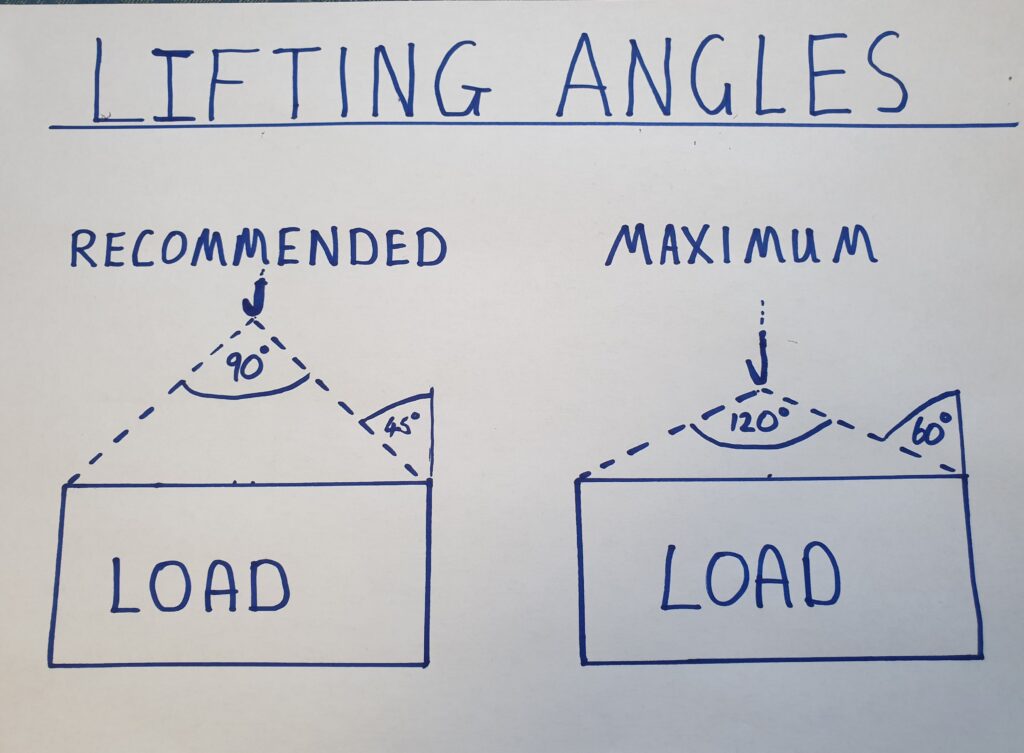

4, LIFTING AND SLINGING ANGLES.

The best way to lift any load is vertical/straight up. Sometimes multi connection points are needed to secure the load, especially on long/wide loads. REMEMBER that the lifting angle (including/working angle) will decrease what the sling can lift as the angle gets bigger. The recommended including angle between the two legs of a sling is 90 degrees. Always read the slings tag.

5, CHECK THE AREA.

Before moving the load, check the route to make sure all precautions are taken to reduce the risk of an accident.

E.g securing the area, doorways are blocked, making sure pedestrian are safe and clear etc.

6, MOVING THE LOAD.

The Make sure loads are carried at ground level. Under NO circumstances must loads be carried over people’s head’s. Hand signals can be used if necessary.

7, LOWERING LOADS.

Always ensure the load has a destination location before moving. Lower loads carefully ensuring the load is stable once in place. NEVER drag material slings or chains from underneath a load, place on runners/skids if necessary.

8, POST OPERATIONAL CHECK.

A check should be completed once the Lifting and Slinging is done.

This is to so you are confident that everything is functioning as it should. Make sure no damage has occurred while using the equipment and report any faults immediately.

9, STORAGE OF THE LIFTING AND SLINGING EQUIPMENT.

All of the equipment should be stored correctly when the job has been completed. Firstly when the equipment is stored correctly it is easily found when you need it again. Secondly, it ensures the equipment is not damaged. Store all equipment in the correct locations. Furthermore it also prevents slipping and tripping accidents in the workplace.

For further information on lifting and slinging procedures the HSE LOLER regulations are a must read.

Don’t forget to visit our website for all our other courses we offer at Keylift Forklift and Safety Training